COPPER

Product

copper cathodes

Standard

BS EN 1978:1998 (Cu-CATH-1), PN-EN 1978:2000 (Cu-CATH-1)

Dimensions and tolerances

(length x width x thickness) in mm:

HMG-S: 910 x 910 ± 10 x 9÷20

HMG-B: 1030 x 1030 ± 10 x 10÷25

HML: 940 x 810 x 20 ± 5

Packing

bundles, cathodes fastened with 1-3 metal tapes

Input material

own concentrates marketed by AL ETKAN INTERNATIONAL TRADE and external charges (concentrates, scrap, copper blister)

Pollution

in accordance with the BS EN 1978:1998 standard, the sum of impurities does not exceed 0.0065%

Application

production of copper semi-finished products such as wire rod, wire, ingots, pipes, sheets and strips, and copper alloys

Producer

Głogów I Copper Smelter, Głogów II Copper Smelter and Legnica Copper Smelter

If you are interested in purchasing this product, please go to the contact form.

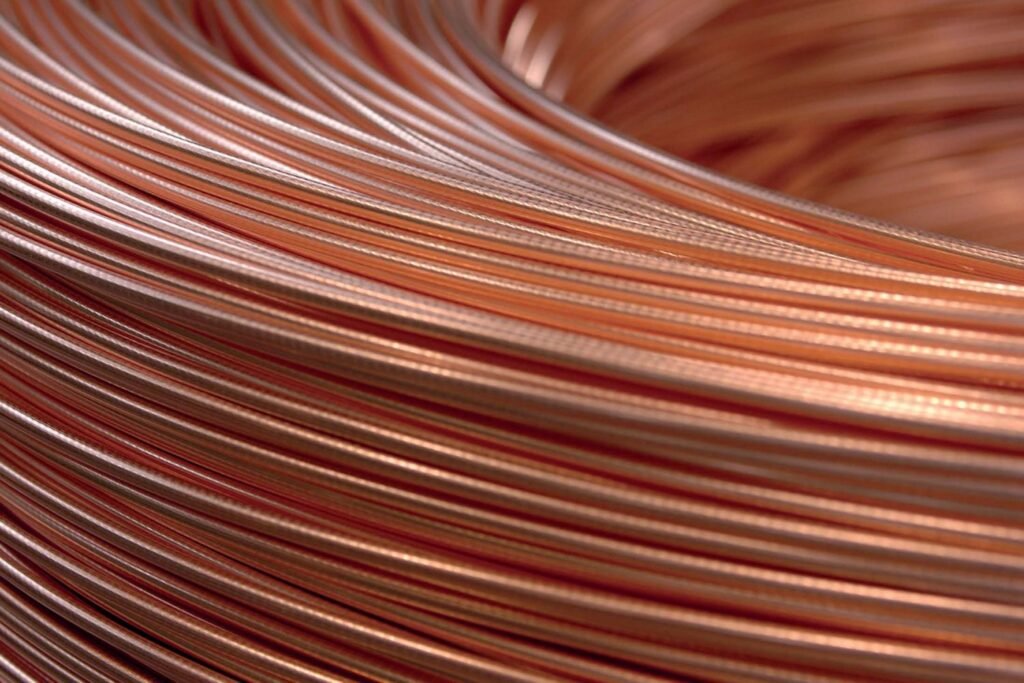

Product

Wire rod with a diameter of 8 mm Cu-ETP-8-CL

Application

Product for broaching on single- and multi-wire machines.

Single wires and strands drawn from wire rod are used to build conductors in cables and electric wires (e.g. enameled wires, car cables, connection cords, etc.).

Wire rod can be drawn in a wide range of diameters on single-wire machines (min. diameter below 0.1 mm) and multi-wire machines (minimum diameter 0.1 mm).

Standard

PN-EN 1977, ASTM-B 49, DIN-1708

Dimensions and tolerances

8±0.4mm

Cleanliness of the material

Pollution level max. 30 ppm O2 = 150-190 ppm (max. 400 ppm).

Batch

Wire rod is produced mainly from cathodes produced in European refineries, Poland and the Netherlands branches in the following grades: Cu-CATH-1

Standard physical properties

Conductivity at 20ºC: min. 58.8 MS/m (101.4% IACS)

Spiral elongation (EN 12893): 450 ± 10 mm or alternative test – AR test: min. 20%

Elongation (200 mm): 44% ± 2%

Breaking strength (200 mm): 225 MPa ± 5 MPa

Annealing capacity A200 min. 20%

Structural properties

The wire rod has a fine-grained structure in which oxygen is evenly distributed. The oxygen content is kept low enough to ensure good ductility and a low recrystallization temperature.

Packing

The wire rod is delivered in coils weighing approximately 4.7 mt, in one section, on wooden pallets, secured with PET straps. Each circle is protected with a stretch polyethylene foil to protect against external conditions.

Pallet dimensions: 1750 x 1750 x 150 mm

Inner diameter of the coil: 1130 mm

Outer diameter of the coil: 1800 mm

Sale

The cargo leaves from origins in Europe, Poland and the Netherlands

Producer

AL ETKAN INTERNATIONAL TRADE marketed copper wire rod by continuous melting, casting and rolling. The production program includes diameters: 8mm ± 0.4mm and 10mm ± 0.4mm.

has a quality certificate in accordance with PN-EN ISO 9001:2015; PN-EN ISO 14001:2015; PN-EN ISO 45001

If you are interested in purchasing this product, please go to the contact form.

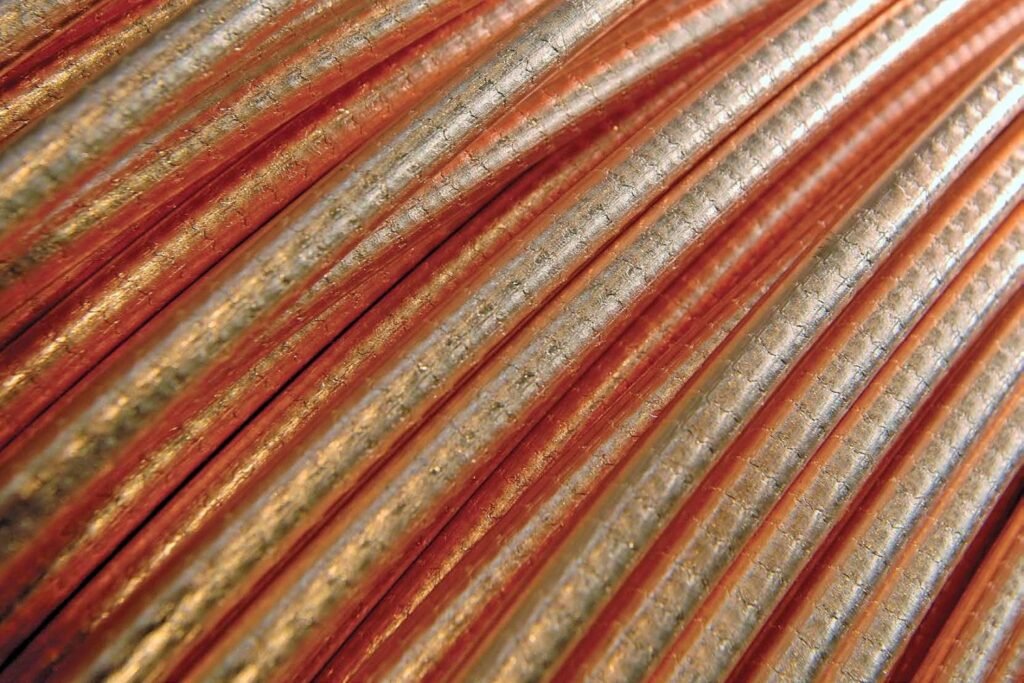

Product

Cu-OFE-8-CL wire, Cu-OFE-12.7, Cu-OFE-16, Cu-OFE-20, Cu-OFE-22, Cu-OFE-24, Cu-OFE-25

Application

for drawing: Cu-OFE wire with oxygen content <3ppm is resistant to hydrogen embrittlement (hydrogenation). A trace amount of oxygen ensures very good ductility and low recrystallization temperature. Very good ductility of the wire allows for very deep drawing to diameters below 0.1 mm (microwires). Drawn Cu-OFE wires are used to construct copper conductors, which can be additionally coated with Ag, Sn or Ni. These types of conductors are used in enameled wires, cables and specialized wires, e.g. in safety cables with increased fire resistance (for IT systems, nuclear power plants), or in category 6 and 7 cables transmitting sound and image.

for extrusion: Cu-OFE wire is an ideal material for continuous extrusion into flat and shaped profiles in the Conform® process.

for rolling: Cu-OFE wire can also be rolled into flat profiles and sections.

Standard

PN-EN 1977, ASTM B49, DIN-1708

Dimensions and tolerances

8mm±0.4; 12.7mm±0.4; 16mm±0.4; 20mm±0.6; 22mm±0.6; 24mm±0.6; 25mm±0.8

Product purity

O2 = max. 3 ppm, maximum pollutant level 25 ppm

Batch

The wire is manufactured using selected quality cathodes produced in European refineries, Poland and the Netherlands branches in the following grades: Cu-CATH-1.

Physical properties

Conductivity at 20°C: min. 58.87 MS/m (101.5% IACS)

Resistance to hydrogen embrittlement: Cu-OFE-8 – min. 10 deflections in the bending test, Cu-OFE-12.7 – no cracks in the single-bending test.

Scale adhesion: assured

Density: 8.92 kg/dm3

Elongation (200 mm): 38%

Tensile strength (200 mm): 180 ± 10 N/mm2

Wire surface

Clean and smooth without cracks and pores, covered with a layer of synthetic wax that protects the surfaces against oxidation during transport and storage. At the customer’s request, the wire can be produced with a wax-free surface.

Packing

Oxygen-free copper wire is delivered in coils weighing up to 4.0 mt, in one section. On wooden pallets, secured with steel straps. Each circle is protected with a stretch polyethylene foil to protect against the harmful effects of external conditions.

Pallet dimensions: 1650 x 1650 x 150 mm

Inner diameter of the coil: 900 mm

Outer diameter of the coil: 1800 mm

Benefits for the customer

The main benefit is the purchase and use of a product with guaranteed, stable, very high quality. The production process is carried out with high technological discipline and using qualitative selection of the input, i.e. cathodes produced at European refineries, Poland and the Netherlands. The technological specificity of the process allows to avoid inclusions and maintain high product uniformity. In relation to wire rod made from the “Contirod®” technology, the customer purchases a product with a narrower diameter tolerance and surface without scales.

Sale

The cargo leaves from origins in Europe, Poland and the Netherlands

Producer

AL ETKAN INTERNATIONAL TRADE marketed oxygen-free copper wire based on the UPCAST technology. The production program includes the production of wires of various diameters (8-12.7-16-20-22-24-25 mm) made of oxygen-free copper and low-alloy copper wires with silver content in accordance with the PN-EN 1977 standard.

If you are interested in purchasing this product, please go to the contact form.

Product

Oxygen-free copper wire containing silver

CuAg0.04(OF)-8, CuAg0.04(OF)-12.7, CuAg0.04(OF)-16,

CuAg0.04(OF)-20,CuAg0.04(OF) -22, CuAg0.04(OF)-24, CuAg0.04(OF)-25

CuAg0.07(OF)-8, CuAg0.07(OF)-12.7, CuAg0.07(OF)-16, CuAg0 .07(OF)-20,

CuAg0.07(OF)-22, CuAg0.07(OF)-24, CuAg0.07(OF)-25

CuAg0.10(OF)-8, CuAg0.10(OF)- 12.7, CuAg0.10(OF)-16, CuAg0.10(OF)-20,

CuAg0.10(OF)-22, CuAg0.10(OF)-24, CuAg0.10(OF)-25

Application

for drawing: due to its low oxygen content (< 0.5 ppm), the wire is suitable for deep drawing with a low recrystallization temperature. Drawn wires can be used to build conductors in cables and wires. Identical to the scope of use of oxygen-free copper wires.

for extrusion: low-alloy copper wire with silver is a material suitable for continuous extrusion into flat and shaped profiles in the Conform® process

other: in commutators of mini engines (washing machines, dryers) and in trolleys due to increased heat resistance and increased abrasion resistance .

Standard

PN-EN 1977

Dimensions and tolerances

8mm±0.4; 12.7mm±0.4; 16mm±0.4; 20mm±0.6; 22mm±0.6; 24mm±0.6; 25mm±0.8

Cleanliness of the material

pollution level max. 15ppm; O2 = max. 5ppm

Silver content

CuAg0.04 (300÷500ppm);

CuAg0.07(600÷800ppm);

CuAg0.10(800÷1200ppm).

Note: At the customer’s request, it is possible to produce Cu Ag(OF) wire with silver content other than those specified above.

Batch

the wire is made of selected quality cathodes produced in European refineries, Poland and the Netherlands branches in the following grades: Cu-Cath-1

Bhysical properties

pollution level max. 15ppm; O2 = max. 5ppm

Cleanliness of the material

Conductivity at 20°C: min. 58.0MS/m (100.0% IACS)

Elongation (200 mm): 38 ± 2%

Tensile strength (200 mm): 180 ± 10 N/mm2

Wire surface

The surface is clean and smooth without cracks and pores, covered with a layer of synthetic wax that protects the surface against oxidation during transport and storage. At the customer’s request, the wire can be produced with a wax-free surface.

Packing

The wire is delivered in coils weighing up to 4.0 mt, in one section, on wooden pallets, fastened with steel tapes. Each circle is protected with a stretch polyethylene foil to protect against the harmful effects of external conditions.

Pallet dimensions: 1650 x 1650 x 150 mm

Inner diameter of the coil: 900 mm

Outer diameter of the coil: 1800 mm

Sale

The cargo leaves from origins in Europe, Poland and the Netherlands

Producer

AL ETKAN INTERNATIONAL TRADE produces low-alloy oxygen-free copper wire with silver based on the Upcast® technology. The production program includes the production of wires of various diameters (8-10-12.7-16-20-22-24-25mm) made of oxygen-free low-alloy copper with silver and oxygen-free copper.

If you are interested in purchasing this product, please go to the contact form.

Producer

AL ETKAN INTERNATIONAL TRADE

Product

ETP 1 granules (Cu min. 99.90%)

OFE granules (Cu min. 99.99%)

STANDARD

Copper granules meeting the requirements of the PN-EN 1977 standard

Dimensions and tolerances

Approximate dimensions of granules: diameter 8 mm, 12.7 mm; length 10-35 mm

INPUT MATERIAL

Cathode grade: Cu-CATH-1

CONTAMINANTS, PPM

Ag<20; Bi<0.3; Pb<3.0; As<1.0; Sb<1.0; Fe<3.0; Ni<2.0; Zn<2.0; Sn<0.5; S<5.0; O2<700 (ETP 1); O2<5.0 (OFE)

PHYSICAL PROPERTIES

Approximate dimensions of granules: diameter 8 mm, 12.7 mm; length 10-35 mm

PACKING

Granules are delivered in big bags weighing approx. 500 kg and 1000 kg.

Other packaging is possible upon agreement with the customer.

DESTINY

Granules obtained from Cu ETP1 wire rod and Cu OFE wire intended for the production of alloys and galvanization processes.

Additional information

There are also granules obtained from the cathode copper production process in O./HM used in agriculture ( granules )

If you are interested in purchasing this product, please go to the contact form.